A lot of people, like me, have had problems with the Autodisk leaking fine powders, and not getting consistent drops when powder granules get underneath the disk. The adjustable charge bar is also a good idea in theory, but can sometimes be less consistent than the disks. I set to making my Lee equipment work correctly instead of buying a more expensive powder dropping system. This is what I did, and the results were fantastic.

These are the tools you will need for these modifications. The piece of glass was from a picture frame and worked great.

![Image]()

I used 400 and 800 grit sand paper to flatten and smooth the 2x0.5 piece of wood. It took a while but I didn't have anything coarser. You will need grits at least this fine later in the process.

![Image]()

After you flatten and smooth the wide side of your 2x0.5, do the same to one of the narrow sides.

![Image]()

Now wrap the 400 grit sand paper tightly around the wood and sand the base of the powder dropper with the flat, smooth side you made on the wood. Follow up with the 800 grit for a really smooth surface. NOTE: Remove the spring and move the actuating arm out of the way. I had everything back together when I took the pictures.

![Image]()

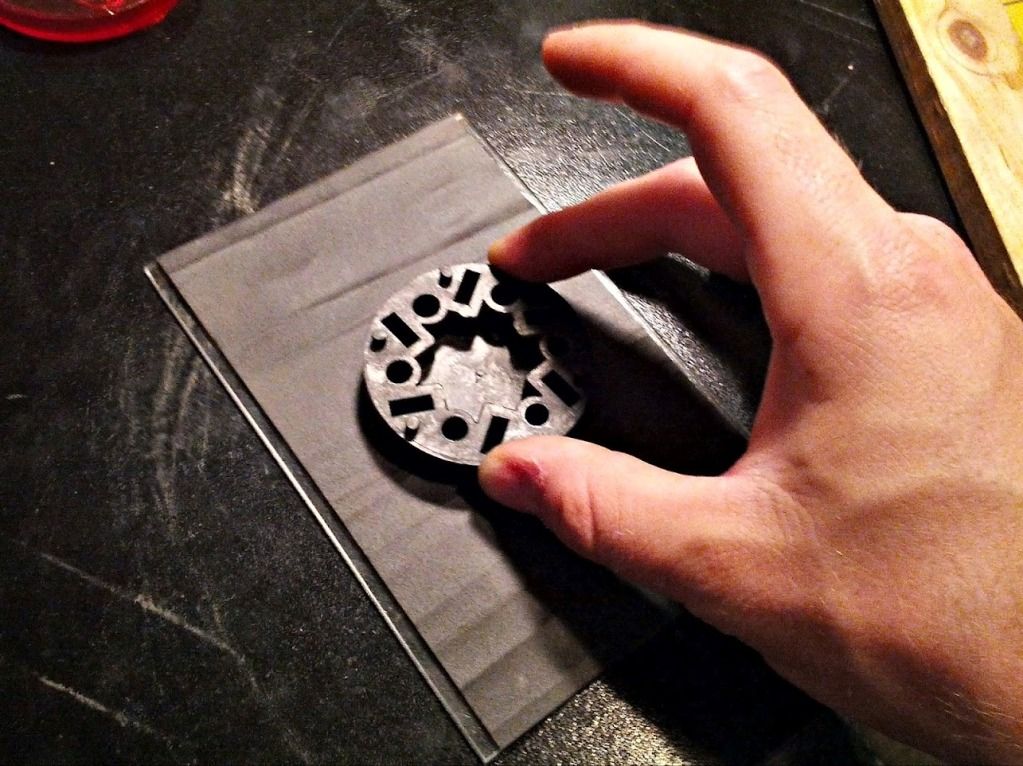

Now sand the top of the disks in the fashion shown. Use light to moderate pressure and circular strokes and follow up with finer grit paper.

![Image]()

Use the small flat edge of the wood to sand in between the nubs on the bottom of the disks. This is tricky because you must try to sand the surface evenly everywhere.

![Image]()

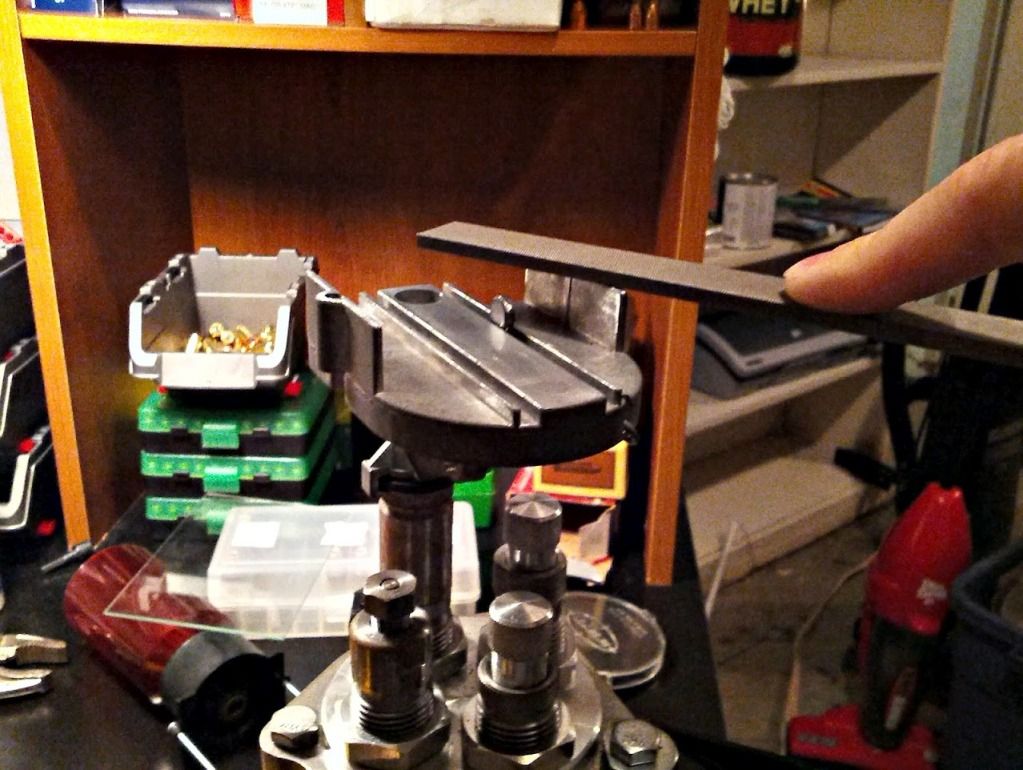

Repeat the process for the Adjustable Charge Bar, but this time you can use the wide side of the wood. This one will take more sanding because the pieces do have a rough fit. To sand the top, remove the slide and sand the top of it in the same manner you did for the top of the disks. NOTE: Removing the slide is important, because that is the part the wiper runs on and you will be sanding a while if you try to bring the rest of the ACB down to that piece. Careful not to break anything when removing the slide.

![Image]()

You've made the parts slightly shorter when they stack together, so now you have to file the walls of the dropper base. I probably took off about .005" - .010" from each side. This can be slightly sloppy due to the design of how the hopper, wiper, and disks stack together.

![Image]()

EXTRA CREDIT:

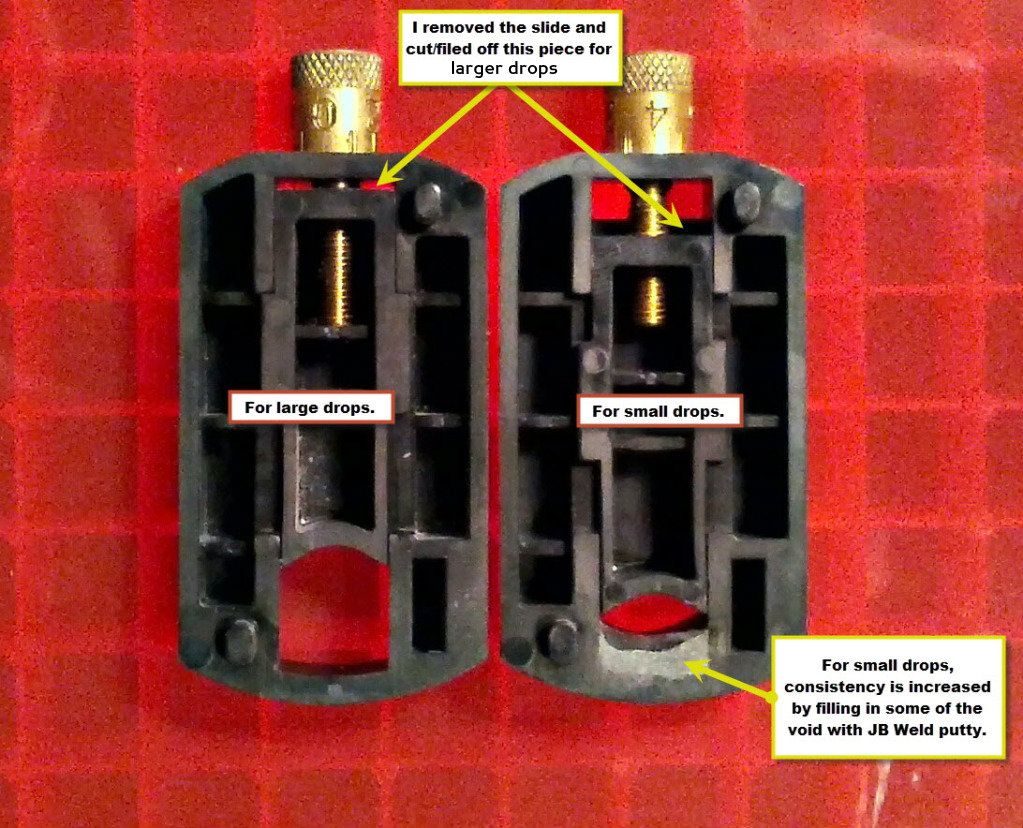

I have two ACBs. One for small drops and one for large (454 Casull loads). These are the modifications I did to them and after smoothing the top and bottom surfaces, they work great. You may want to try these.

![Image]()

NOTE: I have noticed that some of the disk holes now drop up to .01gr lower than they used to. A rat-tail file brought them back to where I had them.

Some or all of these tips may have been posted before, and if so, I apologize. I haven't been reloading that long but I do have an interest in tinkering with my tools, so thank you all for indulging me and I hope this helps someone who feels they're not getting enough precision out of the Lee Autodisk Pro system.

These are the tools you will need for these modifications. The piece of glass was from a picture frame and worked great.

I used 400 and 800 grit sand paper to flatten and smooth the 2x0.5 piece of wood. It took a while but I didn't have anything coarser. You will need grits at least this fine later in the process.

After you flatten and smooth the wide side of your 2x0.5, do the same to one of the narrow sides.

Now wrap the 400 grit sand paper tightly around the wood and sand the base of the powder dropper with the flat, smooth side you made on the wood. Follow up with the 800 grit for a really smooth surface. NOTE: Remove the spring and move the actuating arm out of the way. I had everything back together when I took the pictures.

Now sand the top of the disks in the fashion shown. Use light to moderate pressure and circular strokes and follow up with finer grit paper.

Use the small flat edge of the wood to sand in between the nubs on the bottom of the disks. This is tricky because you must try to sand the surface evenly everywhere.

Repeat the process for the Adjustable Charge Bar, but this time you can use the wide side of the wood. This one will take more sanding because the pieces do have a rough fit. To sand the top, remove the slide and sand the top of it in the same manner you did for the top of the disks. NOTE: Removing the slide is important, because that is the part the wiper runs on and you will be sanding a while if you try to bring the rest of the ACB down to that piece. Careful not to break anything when removing the slide.

You've made the parts slightly shorter when they stack together, so now you have to file the walls of the dropper base. I probably took off about .005" - .010" from each side. This can be slightly sloppy due to the design of how the hopper, wiper, and disks stack together.

EXTRA CREDIT:

I have two ACBs. One for small drops and one for large (454 Casull loads). These are the modifications I did to them and after smoothing the top and bottom surfaces, they work great. You may want to try these.

NOTE: I have noticed that some of the disk holes now drop up to .01gr lower than they used to. A rat-tail file brought them back to where I had them.

Some or all of these tips may have been posted before, and if so, I apologize. I haven't been reloading that long but I do have an interest in tinkering with my tools, so thank you all for indulging me and I hope this helps someone who feels they're not getting enough precision out of the Lee Autodisk Pro system.